The 5-Minute Rule for Dust Extractors For Small Workshops

Wiki Article

Get This Report on Dust Extractors For Small Workshops

Table of ContentsThe smart Trick of Dust Extractors For Small Workshops That Nobody is Talking About7 Easy Facts About Dust Extractors For Small Workshops Shown5 Simple Techniques For Dust Extractors For Small WorkshopsGet This Report on Dust Extractors For Small Workshops

The obstacles for shop dust collection systems focus on crystalline silica dust, carbon monoxide, and also warm, which are toxic mixes. These factors make meeting air quality standards difficult as well as demanding. When choosing a dust control system for a factory, the very first factor to consider is the ability of the device to stand up to severe as well as harmful office conditions.

Covering, or thermal spray, applies heated product to metals to coat their surface areas. Dirt collection systems for this kind of operation have to be particularly created to fit the kind of finishing being used. The objective of the system is to manage and lessen overspray and dirt. The common thermal spray dust control system uses ducts to relocate air to the collection device. dust extractors for small workshops.

It would certainly appear likely to enhance airflow as well as activity, this type of service may be ineffective and also waste power. The design of the booth relies on the force of the air entering the cell or booth. For the majority of systems, it is necessary to have a minor vacuum cleaner in the booth to avoid feasible positive stress.

The Best Strategy To Use For Dust Extractors For Small Workshops

One more method is merely positioning the makeup air connection on the top of the booth. Despite the style, it is necessary for the cleaning of the air to have cross ventilation. Much like a cleanroom, airflow in a thermal spray booth can be either straight or downward, though the downward layout is best for dust collection systems.The pharmaceutical sector is an extremely managed market with substantial and also specific laws. Dirt from pharmaceuticals is generated primarily throughout the production and packaging of products. Each action of generating a medication, that includes granulating, drying out, blending, pressing, covering, and also grinding, produces large quantities of dirt that need to be gotten rid of.

Obstructing and regulating this circulation is the function of the dirt control system. When creating a dust control system for a pharmaceutical plant, the initial consideration is mapping the ventilation system to track the course of dust, fumes, existing air movement patterns, as well as feasible transformative changes. Since lots of pharmaceutical dusts are flammable, the style of the ventilation system is extremely critical.

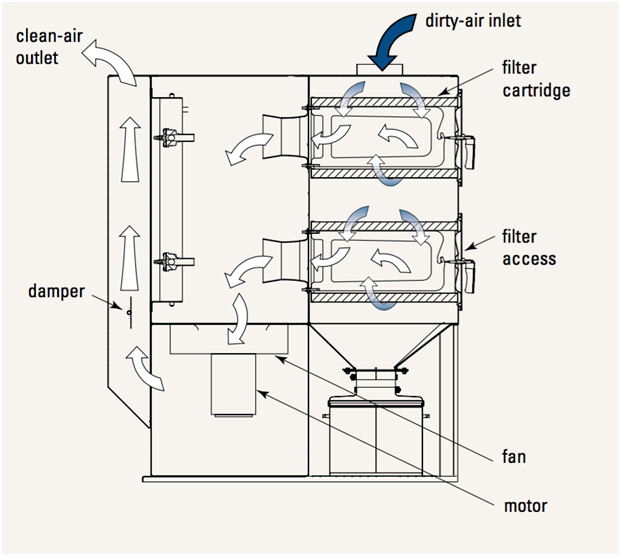

HEPA their website filters are commonly discovered in pharmaceutical dust control systems since they are one of the most effective and dependable. Similar to a shop system, they are set up as a second defense to accomplish zero discharges. Reusing creates a lot of dirt as an all-natural outcome of decreasing things to their raw products.

Dust Extractors For Small Workshops Fundamentals Explained

Dirt stems after materials are shredded, crushed, or have paint or lacquer eliminated. All reusing centers are needed to comply with air quality standards. As they work to meet quality standards as well as control contaminants, they have actually recognized that dust control is a major problem, leading to the broad use dust collection systems to alleviate and also contain the problem. dust extractors for small workshops.When makers choose a dust control system, they are advised by producers about the sort of system that would best fit see their requirements given that acquiring and also installing a dirt control system is a significant investment. Particle matter comes in a wide array of forms, from silicon dust to wood chips and also sawdust.

The Basic Principles Of Dust Extractors For Small Workshops

Fabric filter bags in a cartridge system are one of the most effective technique for accumulating dust. Concrete Cement more information dirt is created throughout the movement as well as transport of the product. Dust collection systems are covered to have the dirt and also tidy the air. Clay Clay dirt is generated in the manufacturing of blocks.Plastic Dust High-Density Polyethylene (HDPE) dust is created in the manufacturing of plastic panels when they are designed and also based on a side trimmer, mill, or miter saw. Paper Dirt Among the more usual forms of dirt is paper dirt, the side result of the manufacturing of different types of paper.

With the intro of dirt collection systems, workers are much safer and a lot more safeguarded. Sugar Sugar dust is the byproduct of the production of candy.

Rice Dust Rice dust has extremely great as well as minute fragments that accumulate during the production of rice-based items. A dirt collection system is needed for the security and security of employees.

Report this wiki page